Application of polymer semi conductive foaming material in digital brush imaging system

| Material name | Foaming density | Foaming density | Volume resistance (m Ω) | Hardness | Electrical conductivity |

| Semi conductive polyurethane foam | 40-60KG/m³ | High rebound | 10E3-10E | 10E3-10E | Positive / negative ionic and electronic composite conduction |

| Semi conductive rubber foam material | 120-200KG/m³ | Black liquid | 10E3-10E | 10E3-10E | Electronic conduction |

Polymer conductive polymer materials:

Polymer conductive polymer materials:

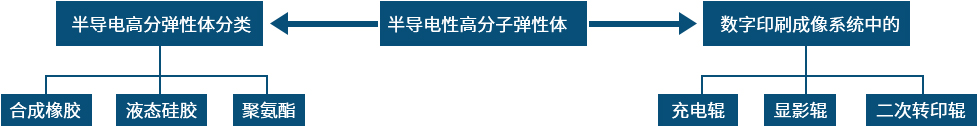

Application of semi conductive polymer elastomer in digital printing imaging system

| Material name | Hardness range | Form | Surface resistance range (m Ω) | Volume resistance range (m Ω) | Electrical conductivity | Environmental adaptation | Resistance drift | Elasticity and pressure change |

| Semi conductive rubber material | 40-80 | Black solid | 10E3-10E | 10E3-10E | Positive / negative ionic and electronic composite conduction | 10-120℃ | 10% | Good elasticity, moderate pressure change |

| Conductive and semi conductive liquid silica gel materials | 10-60 | Black liquid | 10E3-10E | 10E3-10E | Electronic conduction | -15-150 | 5% | Good elastic pressure |

| Semi conductive polyurethane | 30-95 | Colorless or light | 10E6-10E | 10E6-10E | Positive and negative ionic conduction | 10-100℃ | 20% | Good elasticity, poor pressure change |

| Remarks | Working condition at ambient temperature |

半导电性高分子弹性体在数字印刷成像系统中的应用

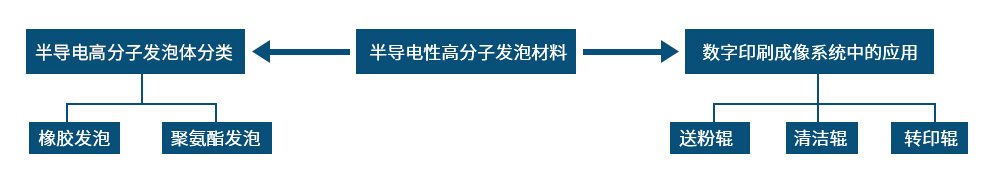

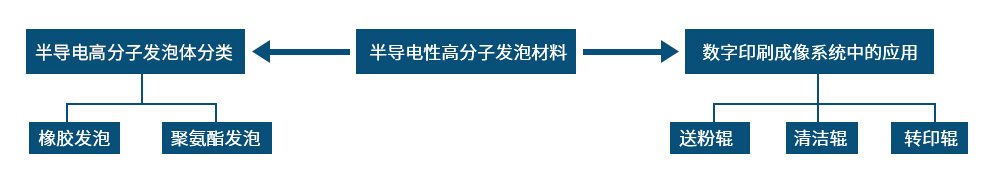

Semi conductive polymer foams:

Semi conductive polymer foams:

Application of polymer semi conductive foaming material in digital brush imaging system

| Material name | Foaming density | Foaming density | Volume resistance (m Ω) | Hardness | Electrical conductivity |

| Semi conductive polyurethane foam | 40-60KG/m³ | High rebound | 10E3-10E | 10E3-10E | Positive / negative ionic and electronic composite conduction |

| Semi conductive rubber foam material | 120-200KG/m³ | Black liquid | 10E3-10E | 10E3-10E | Electronic conduction |

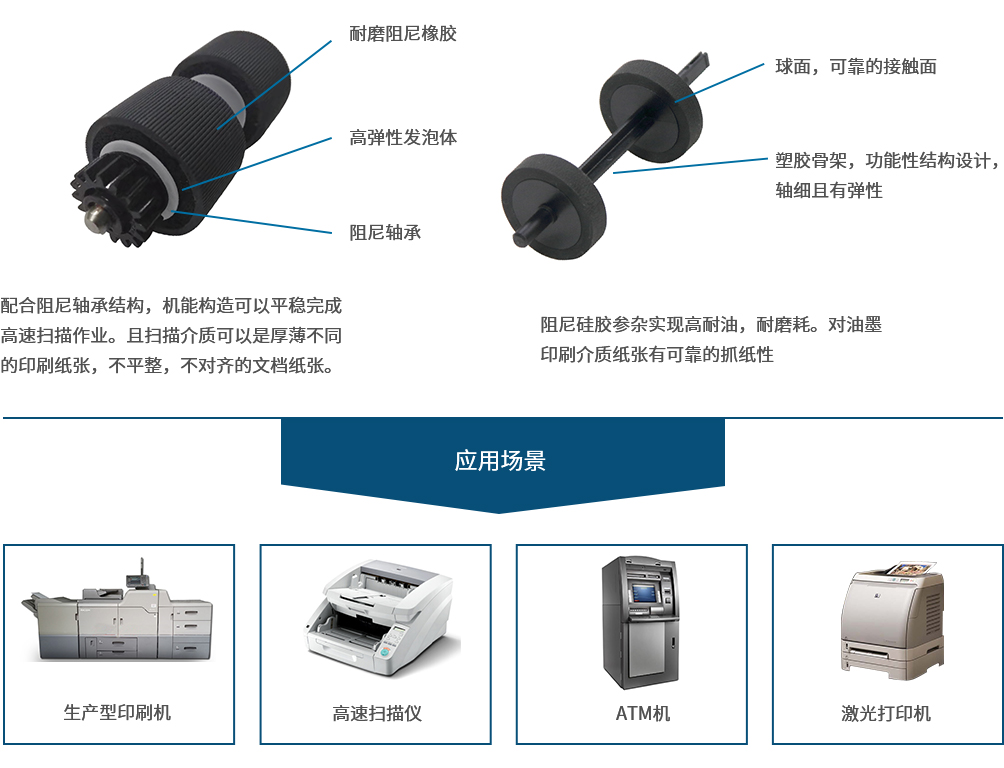

New functional damping polymer materials:

New functional damping polymer materials: With the development of society, OA equipment tends to be high-speed and intelligent. The vibration, noise and fatigue fracture problems caused by polymer based damping materials are becoming more and more prominent. Vibration and noise limit the improvement of mechanical equipment performance, seriously damage the stability and reliability of mechanical equipment operation, and pollute the environment, endangering people's physical and mental health. Therefore, vibration and noise reduction and improvement of man-machine working environment is an urgent problem to be solved.

As a kind of environmental protection products, damping materials are used for vibration and noise reduction of high-speed OA equipment, and its research and development has broad application prospects.

Polymer based damping materials have a wider application prospect due to their light specific gravity, easy processing and large internal friction.

The vibration absorption mechanism of traditional polymer damping materials is based on viscoelastic damping, so its applicable temperature and damping performance strongly depend on the glass transition temperature of polymer. The vibration absorption mechanism of polymer based damping materials is based on the conversion loss of vibration mechanical energy, electrical energy and thermal energy rather than the traditional viscoelastic damping, so it does not depend on the glass transition of polymer matrix, which will greatly expand its application temperature range. Because this kind of damping composite can theoretically use any kind of polymer as the matrix, it has the incomparable advantages of traditional polymer vibration absorption materials.

Using functional additives and polymers to prepare organic hybrid damping materials can not only greatly improve the damping peak height, but also adjust the position of the damping peak, which is a promising damping modification method. The company uses synthetic rubber, organic silica gel, polyurethane and other organic polymer materials as the polymer base to develop a series of functional damping polymer elastomer materials. It can adapt to the needs of different temperature range, different environment and different media.

Environment friendly coatings:

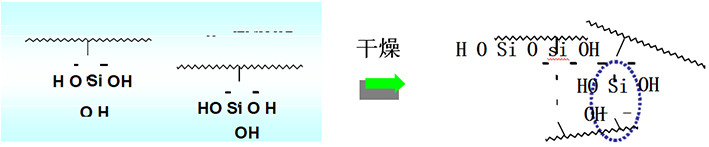

Environment friendly coatings: Conductive coating is a kind of functional coating which gives objects the ability of conducting electricity and eliminating accumulated static charges. The conductive mechanism of the composite conductive coating is that the conductive fillers contact with each other to form a continuous network chain. The carrier can move in the chain, so that the coating has conductivity.

Our waterborne polyurethane conductive coating is a kind of coating with waterborne polyurethane resin as base material, nano conductive material and other additives, and water as dispersion medium. The waterborne polyurethane conductive coating modified by crosslinking has good storage stability, film mechanical properties, water resistance, solvent resistance and aging resistance, which is similar to the traditional solvent based conductive coating.

We can choose different waterborne polyurethane coatings and different conductive materials according to the characteristics of printers, and develop special coatings to help customers solve various problems. We always adhere to do environmental friendly coatings, harmless to the human body, with water as the medium, harmless to the environment.

1、 Differences:

1. The carbon black used in traditional conductive coatings is conductive and oily. Oily coating (non reactive film-forming): the film-forming material is various synthetic resins, belonging to the solution coating. In the film-forming process, it only needs to wait for all solvents and diluents in the coating to evaporate, and then agglomerate to form a film. Some varieties need to be heated properly or through catalysis to polymerize the resin into film, and the film-forming material is non reactive. Non reactive film-forming material is composed of linear polymer dissolved or dispersed in liquid medium. After coating, polymer film is formed due to volatilization of liquid medium. With thermoplasticity - softened by heat and hardened by cold. It belongs to physical reaction, and its stability is relatively poor

Waterborne coating (reactive film forming): the film forming material is mainly emulsion, and water as diluent coating, including oil emulsion coating and resin emulsion coating, reacted film forming material composed of reactive oligomers and monomers, etc., and coated on the surface of the material, forming a tough film under certain conditions through polymerization or condensation reaction. Thermosetting - forming an impermeable network polymer. It belongs to chemical reaction, and the molecules are connected by bond (ionic bond or covalent bond), and the stability is good.

2. Waterborne polyurethane is a new type of polyurethane system, which uses water instead of organic solvent as dispersion medium, also known as water-borne polyurethane, water-based polyurethane or water-based polyurethane. Waterborne polyurethane is a kind of water-based polyurethane, which has the advantages of no pollution, safety and reliability, excellent mechanical properties, good compatibility and easy modification.

2.2 conductive dispersion is a kind of long-term and stable conductive dispersion which evenly disperses conductive powder into water-based system by means of science and technology. The high concentration dispersion colloid with pH of 7-8 and solid content of 50% has good compatibility with waterborne polyurethane. By combining the two and adding some other additives, the semi conductive coating with stable conductivity and no settlement can be made.

This conductive coating has high surface drying speed, low cost and good performance.

3. The coating has no pollution to OPC and no adhesion to developer.

4. The water-based coating has no pollution to the environment and can be hydrolyzed. Meet the requirements of environmental protection.

405, Building 5, Yilisheng Industrial Park, No. 602, Fengtang Avenue, Tangwei Community, Fuhai Street, Bao'an District, Shenzhen

0755-33885033 33885055

sales@szdlkj.com